Printable Hydraulics

Printable Hydraulics: A new method for fabricating force-transmission elements within robots

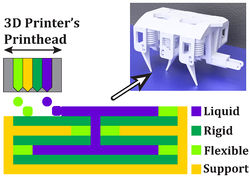

Multi-material additive-manufacturing techniques offer a compelling alternative to conventional rigid and soft robot fabrication techniques, allowing materials with widely varying mechanical properties to be placed at arbitrary locations within a structure, and enabling design iterations to be rapidly fabricated with trivial effort. This capability enables complex composite materials with new bulk properties, and in contrast to virtually all other fabrication techniques, the incremental costs of additional design complexity when using additive manufacturing are zero. We show how commercial multi-material 3D printers can be adapted to co-fabricate solids and fluids within the same 3D-printed structure, demonstrating a new capability for transmitting force within 3D-printed assemblies: Printable Hydraulics.

Publications:

-

Robert MacCurdy, Robert Katzschmann, Youbin Kim, Daniela

Rus

- Printable

Hydraulics: A Method for Fabricating Robots by 3D

Co-Printing Solids and Liquids 2016 IEEE

International Conference on

Robotics and Automation (ICRA)

Design Files:

Videos:

Automated assembly of integrated robotic structures

| Printed Hydraulics Overview | Printed Hydraulics parts are fabricated layer-by-layer, by depositing adjacent droplets of liquids and solids |

This method, based on inkjet deposition of photopolymers and

non-polymerizing fluids, can achieve resolutions better than 100μm,

allowing the fabrication of complex channels for fluid routing and

capillary structures for selectively distributing hydraulic pressure to

regions of the assembly with precisely graded elasticity, enabling

prescribed movements in response to pressure changes. Control of

complex composite assemblies fabricated in this manner is simplified

because the working fluid is incompressible; because the solid and

fluid regions are fabricated together, there is no need to purge air

bubbles or remove support material. The key idea of this approach to

robot fabrication is to automate the assembly of complete robotic

structures. By reducing or eliminating assembly steps, this method

breaks the connection between design complexity and fabrication

complexity, allowing complex designs to be fabricated with trivial

effort.

Basic Transducer Unit: the Bellows

|

|

The achievable feature sizes of drop-on-demand inkjet printers are too

coarse to print sliding seals; they would leak. As a result,

conventional piston designs are not practical. An alternative design

using a bellows avoids the need to have seals entirely. As the pressure

inside the bellows increases the material deforms and the bellows

extends. This deformation can be estimated using finite element

modeling tools to ensure that the stress and strain in the printed

material does not exceed allowable limits. The bellows design is

inherently modular: if greater actuator extension is required

additional folds can be added, and if larger force is required (for a

given input fluid pressure) the cross-section of the bellows can be

increased.

Fabricating a robot in a single step

|

|

|

|

We designed a tripod-gait hexapod with a single rotational degree of

freedom (DOF), illustrated above. All mechanical components

of this robot are printed in a single step with no assembly required.

This robot weighs 690 g, is 14 cm long, 9 cm wide and 7 cm tall. The

legs are designed with a neutral position that inclines their major

axis 60 degrees above the floor and each leg is actuated by a bellows,

causing the leg to rotate 10 degrees in either

direction, relative to this neutral position. Three of the legs are

inclined toward the front of the robot (bank A) and three are inclined

toward the rear (bank B). Each driven bellows is internally connected

to a corresponding

driving bellows via a fluid channel that runs through the robot’s body;

the fluid in each driving/driven bellows pair is isolated from the

other bellows. The three driving bellows from bank A are kinematically

linked and attached to a crankshaft via a connecting rod. The bellows

from bank B are similarly connected to a separate section of the

crankshaft that is 90 degrees out of phase. The crankshaft is turned at

30 RPM by a single geared DC motor consuming approximately 2 W (Pololu

#3070), yielding a locomotion speed of 0.125 body-lengths per second.

This arrangement moves the legs from the two banks 90 degrees out of

phase with each other, enabling forward or backward locomotion without

an additional DOF at each leg, and does not require the feet to slide

on the floor.

Applications to Soft-Robotics

|

|

|

|

Soft robots are usually fabricated via cast elastomers, and although

casting soft robots is often faster than assembling conventional rigid

robots, the mold-making process can be time consuming, and embedding

multiple materials within a cast object via overmolding adds

complexity. Additionally, producing complex, graded materials via

casting is difficult. Additive manufacturing, combined with the printed

hydraulics approach, provides an alternative fabrication method for

soft robotics that is automated, flexible, and enables geometries that

are infeasible with other production methods. As a demonstration of the

utility of printable hydraulics to the soft robotics community, we

designed and printed a two-finger soft gripper, shown above. The design

process required four iterations. Each iteration required 3.5 hours to

print and a short time to evaluate the performance of the part. This

method is faster and more automated than soft robot fabrication

approaches that rely on casting materials into molds. Additionally, the

final gripper design incorporates thin channels and internal fluid

routing that would be difficult to achieve via casting.

Printed Gear Pumps

|

Gear pumps are low-flow, high-pressure devices, are commonly employed

in hydraulic systems, and are capable of

producing continuous flow. We designed and printed a gear pump to

present an alternative to the bellows pump, which

produces only reciprocating flow. These pumps employ a pair of enmeshed

counter-rotating teeth enclosed in a tight-fitting housing. Fluid

trapped between the teeth and the housing is moved from the

low-pressure port to the high pressure port, and is prevented from

moving back by the meshed teeth near the center of the pump. The gears

have a pitch diameter of 17.5 mm, an outer diameter of 19.6 mm, a

modulus of 1.25, and a gear height of 8 mm. We followed the common

practice of using involute gears with a 20 degree pressure angle.