Automated Design & Fabrication of Robots

Building robots via conventional practice requires painstaking design and assembly steps that rely heavily on human intuition and individual expertise. I develop algorithms and fabrication techniques that automate the design and production of customized robots in order to accelerate this process, with the goal of automatically designing robots that "walk out of the printer". My research creates design synthesis algorithms and manufacturing technologies, with the goal of a unified software and hardware tool chain that can automatically synthesize, evaluate, and fabricate electromechanical devices. The simple description is: "robots creating robots".

I believe that realizing this goal will require a modular design and construction method that employs a small set of simple modules (cells) that are deployed in large assemblies to solve a specific task, an approach that I call "Multicellular Machines". The robot design process is recast as a search over the position of modules in the assembly; fabrication is accomplished via the ordered placement of modules. I am working to address several key automation challenges: fabricating robot bodies, fabricating robot "brains", and designing both.

The results below demonstrate my efforts to address each of these challenges, in isolation:

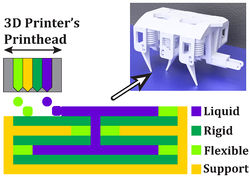

- The Printed Hydraulics technique shows how commercially available 3D printers can be modified to automatically fabricate hydraulically-actuated assemblies that do not require manual assembly.

- The BitBlox modules demonstrate how a heterogeneous modular design technique can be used to create high-performance electromechanical assemblies.

- Hybrid Printing uses miniaturized heterogeneous modules and combines them with existing additive manufacturing techniques to automatically produce high-performance electrical circuits.

- These modular assemblies can be designed using a generative representation that leverages evolutionary computation to explore the design space, allowing many pareto-optimal candidate designs to be evaluated when only general design objectives are specified (like: "design a fast robot").

- Where a more specific design objective is known (for example, a netlist is specified), constraint satisfaction methods can be applied to search over the design space until a satisfying module placement is found.

My future work will combine these techniques to permit entire electromechanical machines to be automatically designed and fabricated. This capability could transform the ways that robots are used, allowing robots to be rapidly adapted to new challenges, permitting the deployment of large swarms of low-cost machines, or enabling single-use expendable robots for hazardous environments.

Automated Fabrication: Printed Hydraulics

This work introduces a novel technique for fabricating functional robots using 3D printers. Simultaneously depositing photopolymers and a non-curing liquid allows complex, pre-filled fluidic channels to be fabricated. This new printing capability enables complex hydraulically actuated robots and robotic components to be automatically built, with no assembly required.

- See the Printed Hydraulics project page for more information.

Automated Fabrication: Printable Programmable Viscoelastics

This

work demonstrates a new method for 3D printing viscoelastic materials

with specified material properties. This method allows arbitrary

net-shape material geometries to be rapidly fabricated and

enables continuously varying (yet fully-specified) material properties

throughout the finished part. This new ability allows robot designers

to tailor the properties of viscoelastic damping materials in order to

reduce impact forces and isolate vibrations.

- The IROS paper on this work is available here.

- Also watch our video.

|

|

|

|

Automated Fabrication: BitBlox - Printable Electromechanical Modules

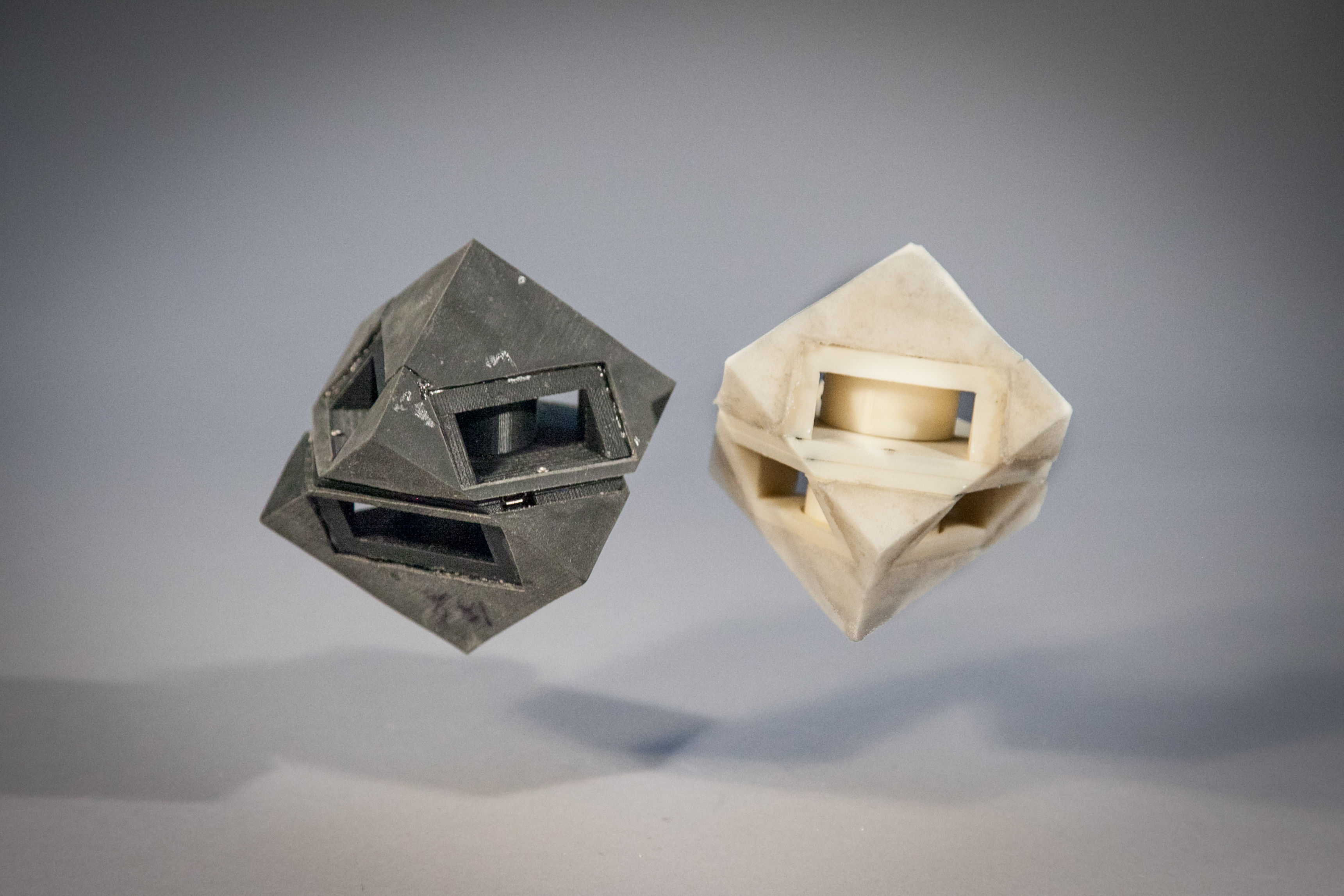

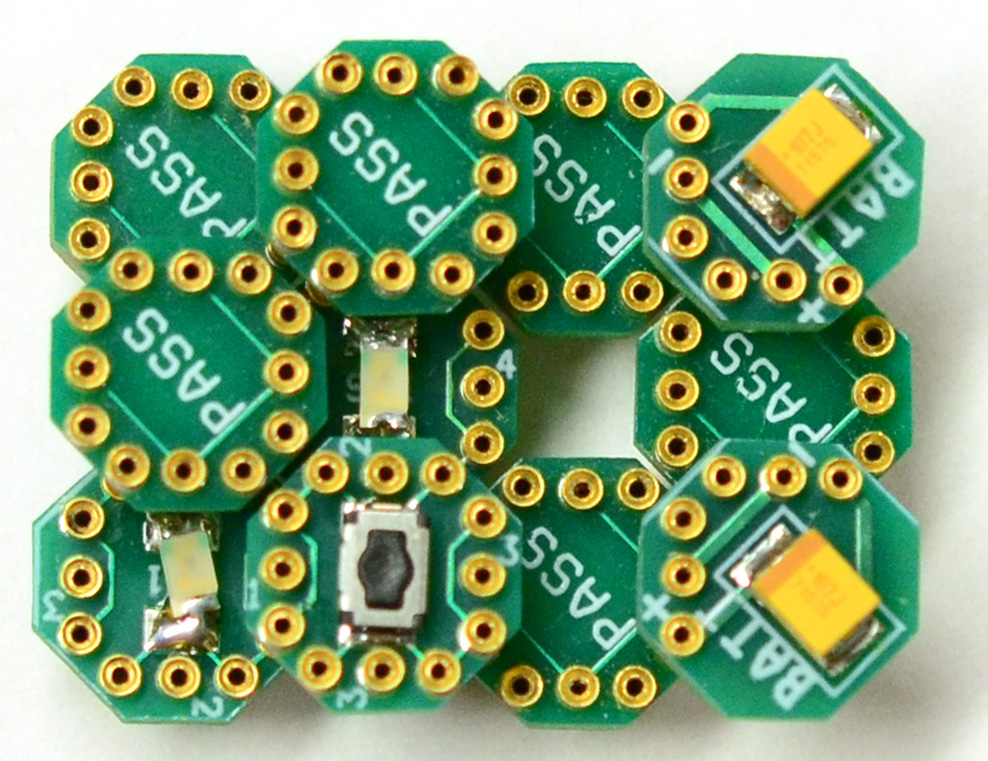

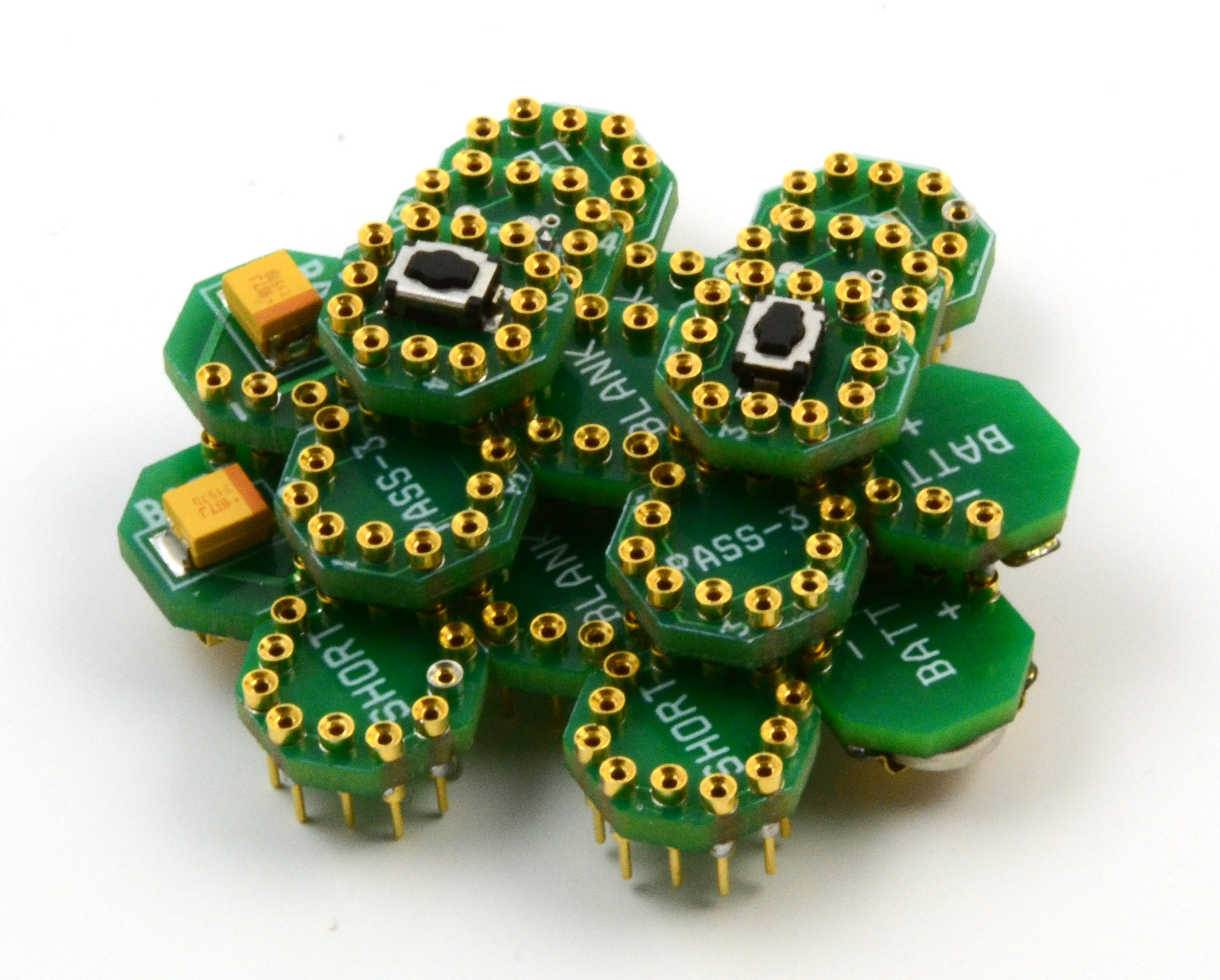

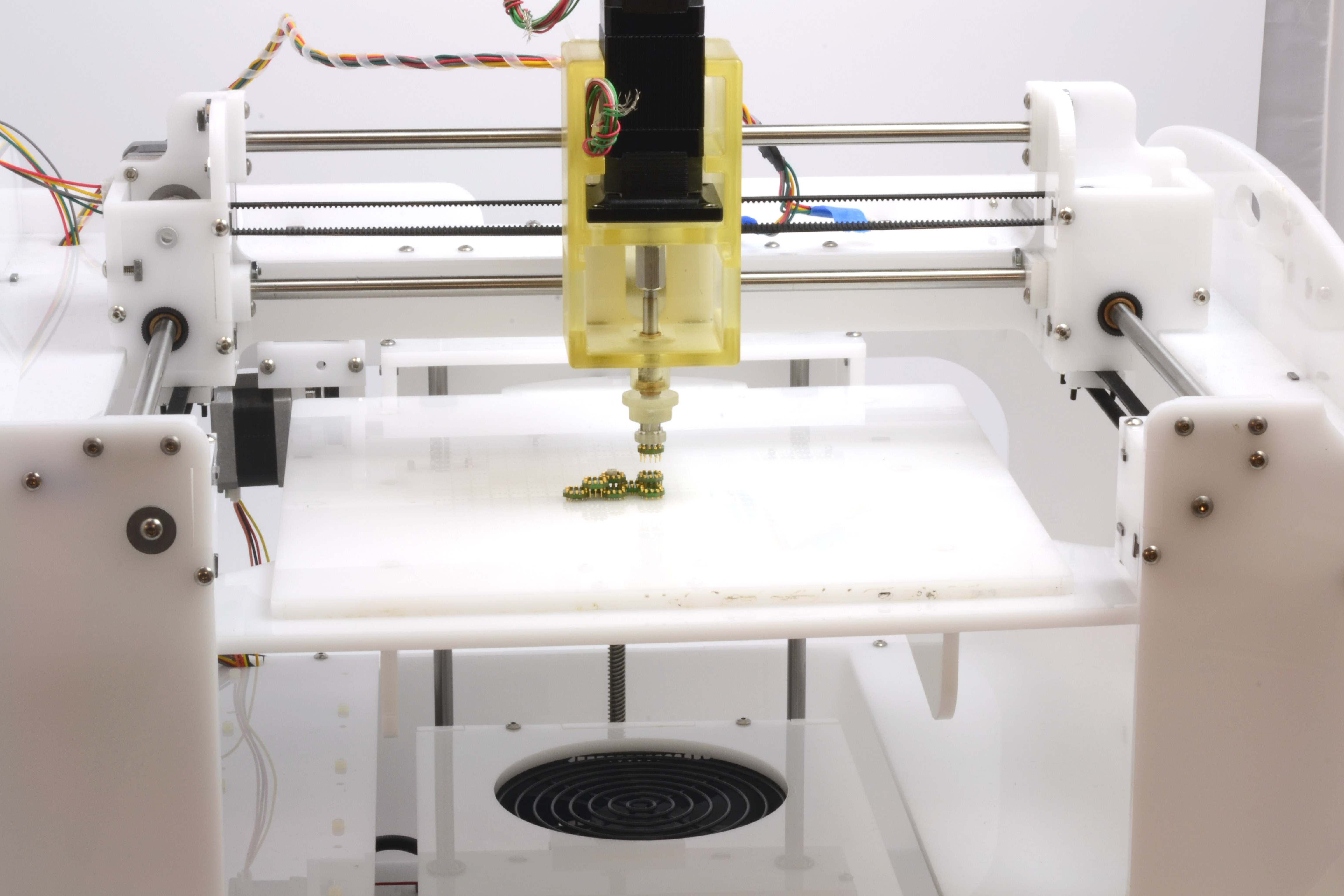

Printing large-scale electromechanical parts from raw materials is not currently feasible because state of the art printers and inks yield large transistors with low performance. Instead, electromechanical assemblies can be built, automatically, from small heterogeneous modules: BitBlox. BitBlox are small, modular, interconnecting blocks that embed simple electromechanical connectivity and functionality. They can be automatically placed by a 3D printer. Not all blocks are identical; instead the unique combinations and positions of BitBlox within an assembly determine the mechanical and electrical properties of the assembly. BitBlox can be used to build recyclable electrical circuits and robots.

- The IJRR paper on this work is available here.

- Watch this video showing the fabrication of a working infra-red remote control

- This video shows a simulated and real inchworm robot fabricated with BitBlox modules.

|

|

|

|

Automated Fabrication: Hybrid Printing

This paper is in review

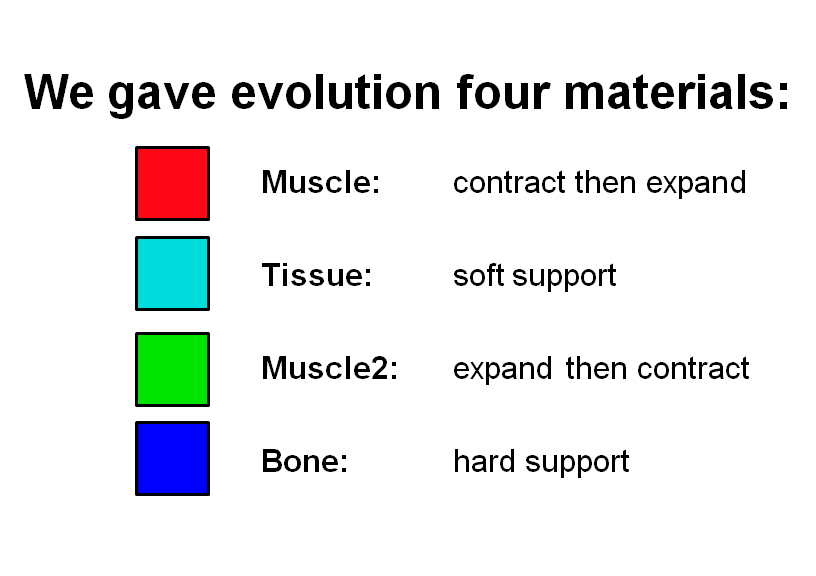

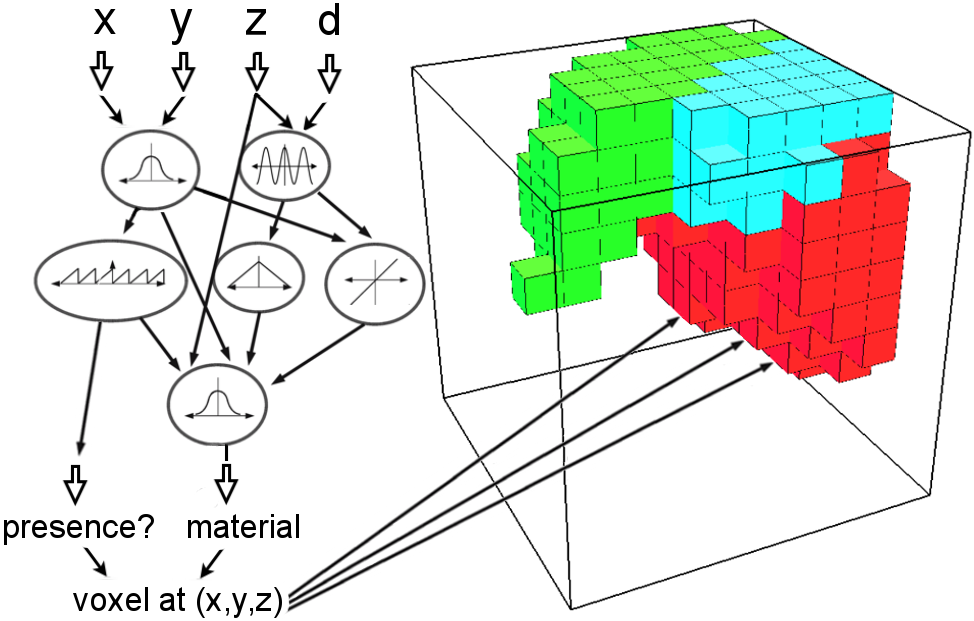

Design Automation: Evolving Modular Robots with a Generative Encoding

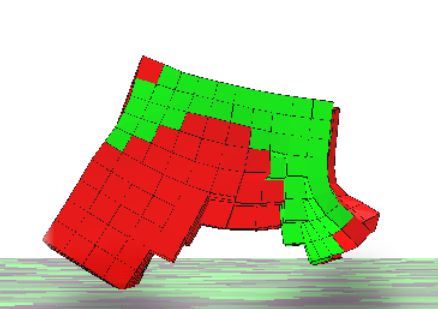

Designing modular robots that employ heterogeneous modules aligned with a grid can be accomplished via search over the occupancy matrix that specifies the module type in each grid cell. A generative encoding (NEAT) creates a network that yields the module type in each cell when queried with the cell's grid position. Each individual (simulated) robot created in this way participates in an evolutionary competition to pass on parts of its generative encoding to the next generation, with faster individuals more likely to pass on their genes. This approach allows the high-dimensional design space to be explored and yields many qualitatively unique solutions that all move quickly - an approach that aids design discovery.

- The ACM SigEvo paper on this work is available here.

- Watch this video showing the evolution of many different multicellular robots that all move quickly, but with very different strategies.

|

|

|

|

Design & Fabrication Automation: A System for 3D Printing Functional Machines with Digital Materials

This paper is in review

Design & Fabrication Automation: 1D Printing of Recyclable Robots

This paper is in review